ITS TIME TO BUILD YOUR WALL.

This post contains affiliate links. If you click through and make a purchase, I may earn a commission at no extra cost to you.

Start Deciding

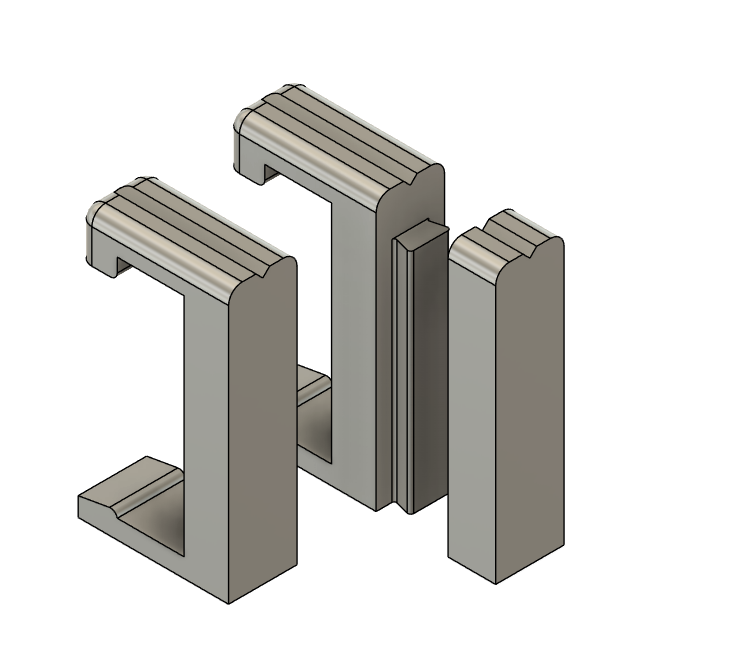

Choose your bracket system

This is the standard bracket system. A good balance of strength and utility while not being too large to fit on a wall.

Do you want to glue this to a panel to mount or do you want to mount this directly to a wall?

Wall Mount

More load support – Directly screwing the brackets to studs increases the load bearing capability of the installation.

- More Permanent

- More precision needed during installation

- Restricted based on stud locations

Panel Mount

Less load – Panel mounting requires gluing to a panel that is then mounted to the wall. Weight limits are subject to the glue used to stick it all together.

- More portable, ideal for non-permanent installations

- More flexible with spacing and location.

How many columns do you want?

I recommend 2 ft of spacing between each bracket column and 1 ft of free hanging end if doing a panel mount. So for a 4ft wide panel you could have as few as 2 columns. (1ft,C,2ft,C,1ft). At 6 ft you would get 3 columns. Etc,etc.

Wall mount spacing will be determined based on the studs in your wall. I recommend 1 column per stud.

How many horizontal boards do you want?

Each board section needs 4″ of vertical space(2.5″ for the board +.5″ for the bracket above the board. +.5 inch for the bottom bracket shoe spacing below the bottom most board. So you get 4 boards per 1 ft of vertical wall space(essentially) You could have a single board setup but we suggest at least 2 horizontal boards. You will need to math out how many you want for your setup.

Start Shopping

Horizontal Boards

Refer to the table below and select the appropriate boards.

Bracket System

1×3

Actual dimensions are 2.5″x.75″. and these can be had in almost any length you need.

Fasteners

The OTW system is standardized around 1/4×20 hardware. For each horizontal board on each column of brackets you will need:

Filament

I used PLA Pro for mine, its what I had on hand. Really almost any filament will work with some caveats based on your environment. I would avoid any art-type filaments like PLA Silk. Additives of this type make the parts weaker in general.

A few of my favorites:

GreenGate 3D PETG

Polymaker (PLA Pro)

Oveture (PLA+)

Start Printing

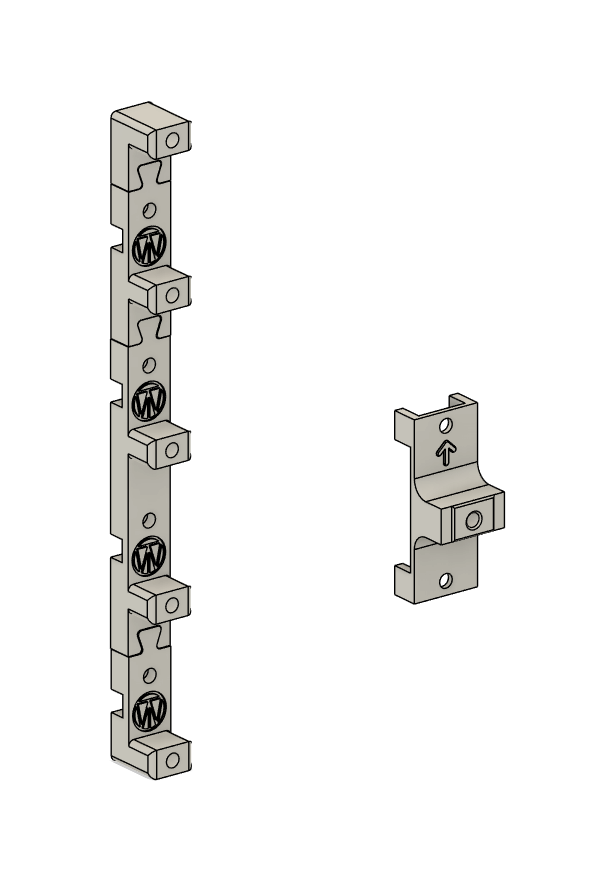

It starts with this basic set of wall brackets.

The recommended print settings are 6-10 walls at 60% infill. This is not a hard and fast rule and your mileage may vary. I suggest printing a small set to test with initially by hanging weights or sandbags from it to find the specific failure point for your filament/print profile combination.

Each column will need 1 cap and 1 shoe, as many body brackets as your setup demands.

Build your wall

A full video guide will be coming soon.

Panel Mounting

Step 1 – Setup

Gather together all your materials:

- Wall Brackets ( 1 Cap, 1 Shoe, As many main bodies as you decided.)

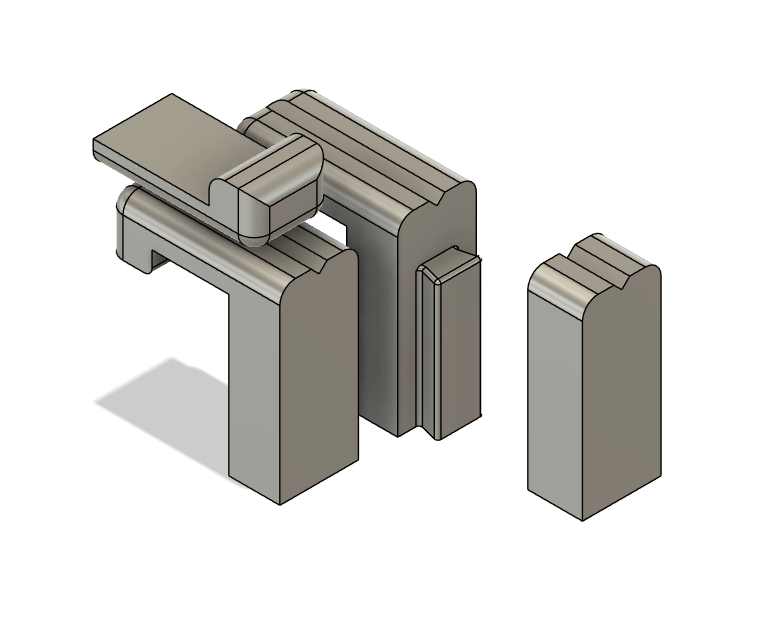

- Drilling Jig

- Tools

- 1x4x20 Nut

- 1.25″ 1x4x20 bolts

- 1/4″ washer

- Caulking Gun

- Adhesive

- Level

- Straight Edge

- Pencil

- Screwdriver

- Drywall screws

- Wrench

- Stud Finder

- Drill

- 5/16th” Drill Bit

Start by cleaning up the support material on your wall bracket prints.

Step 2 – Assemble the Panel.

- Set the panel on a flat surface large enough to fit your boards (we will need them to ensure spacing and alignment of the brackets.)

- Measure 1-2 inches from the left and right sides of the panel.

- With the pencil mark a vertical guide line from the top to the bottom of the panel.

- Install a 1/4″ Nut in the recess on the back of each bracket (except the cap)

- Apply the adhesive caulk to the backside of the bracket starting with both caps.

- Align on the panel as desired.

- Continue installing brackets in pairs in this manner. Each time a board channel is completed, set a board in it to ensure proper alignment.

- When bracket installation is finished set something heavy over each column of brackets to ensure adhesion and wait to dry.

- If more columns are required for your assembly, remove the boards and glue the columns to the panel following the previous steps.

Step 3 – Panel Installation

- Locate where on your wall you want your panel.

- Get the stud finder and find the studs within that area. Mark them in a manner that will be visible with the panel on the wall.

- Remove the weights and boards from your panel and hold the panel up against the wall.

- using the stud location marks as reference screw the panel to the wall ensuring that it is level.

- Once mounted, get the drilling jig and a board.

- Align the board as desired on the wall/panel.

- Use the place the drilling jig so its alignment features straddle the board and bracket column.

- Place the 5/16th” drill bit in the aligning hole and drill a hole in the horizontal board.

- Be careful not to drill too far and mess up the nut. There should be a perceptible drop in force required once the drill bit comes through the back side of the board.

- Remove the drilling jig and install the 1.25″ 1/4×20 bolt and washer.

- Repeat for each column and each board.

More Printing

Now head into our library of stuffs and start printing your accessory brackets.

Or download our blank accessory bracket templates and build your own.

Leave a Reply